GRP Piping System

Serving Fluid Industries

Preserving The Environment

Environmental friendly

because of low coefficient of frication, less pumping energy is needed during pipeline operation

Long Life Span

Durable pipe material which will stay in service for 50 years and more

Cost Effective Installation

Low weight of GRP pipes and versatile jointing methods saves money and time

Resistance to Corrosion

Resistant to soil and fluid corrosive material

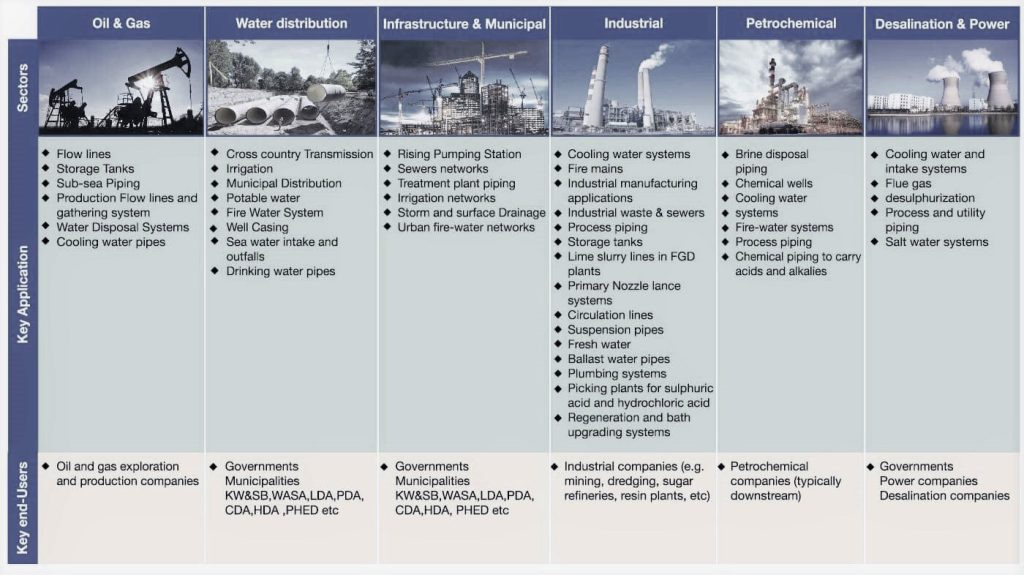

In recent times, the world has realized the need to move to a pollution-limiting, environment friendly, corrosion resistance and future-looking business scenario. Those in the conventional material piping domain, appreciate that better than most. Hence the buzz word in today’s piping industry is “Glass Reinforced Polymer (GRP) Products”. Use of fiber reinforced polymer (FRP) composites for construction of new pipeline infrastructures and rehabilitation of existing ones has increased significantly over the past decade. We see a rapid transition from conventional Piping systems to advanced composite GRP pipe

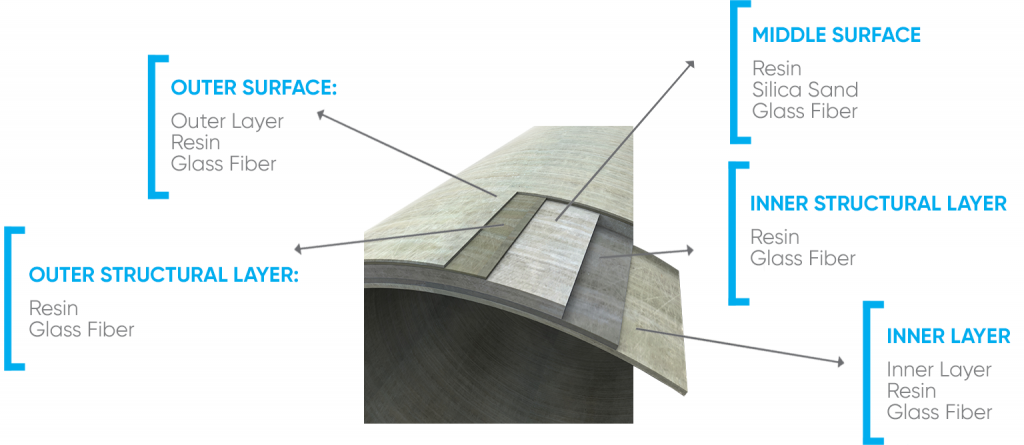

Fiberglass pipe is made from glass fiber reinforcements embedded in, or surrounded by cured thermosetting resins of different types such as unsaturated isophthalic, Orthophtalic, vinyl ester resins. This composite structure may also contain aggregate fillers to add additional stiffness for underground installations and pigments to outer layer of pipe to protect it from sun’s UV radiation. By selecting the proper combination and types of resin, glass fibers, fillers, and proper design, AvisaParseh creates piping system that offers a broad range of properties and performance characteristics for variety of applications.

Technology That Yields Higher Performance Products At Lower Cost

AvisaParseh GRP pipes are produced using Filament Continues Winding process. Using technology developed by material specialists, a very dense laminate is created that utilizes the contribution from three basic raw materials. Continuous glass fiber rovings and choppable rovings are incorporated for high hoop strength and axial reinforcement. A sand fortifier is used to provide increased stiffness with placement near the neutral axis, in the core. All materials are embeded in resin matrix which acts as bonding material . This cost effective process yields high performing composite GRP pipe which has wide application in various industries.

Bi-Axial GRP Pipes

Originally designed for transferring potable water and underground installation, today GRP pipes are being used in various industries where the pipelines must be installed aboveground.

Our Solution is Biaxial piping systems. Our Biaxial pipes are a semi-steel products in terms of mechanical properties where the pipeline can withstand radial and axial forces forces in radial and axial direction at the same time providing corrosion and thermal resistance required in rough operation conditions.

Uni-Axial GRP Pipes

AvisaParseh Uniaxial Filament wound GRP pipes are designed for underground installation. Uniaxial pipes are designed to support hoop stress (radial and tangential) directions supporting external loads (live and soil loads) as well as internal pressure of fluids on the pipe wall.

light weight, ease of installation, fast and easy pipe jointing systems (mechanical GRP couplings) and long cycle life makes these pipes the best choice for underground piping systems

Pipes For Trenchless Applications

In order to install, replace or rehabilitate existing underground piping infrastructure with minimal disruption to surface traffic, business and other activities and to minimize the operational cost as well as overall social costs AvisaPraseh has designed special grade of GRP piping system for trenchless installations.

Thanks to the new technology, AvisaParseh produces jacking pipes up to 3000 mm in diameter, and pressure class of 32 bars which could withstand jacking force of 700 tons.

| Diameter Range | 300-3000 mm |

| Pressure Rating | up to 32 bar (depending on pipe diameter) |

| Stiffness Class | up to 10000 Pa |

| Standard Length | 12 meter |

- Potable Water

- Municipal Sewage

- Irrigation

- Surface and Storm Water Collection

- Waste Water Treatment Systems

- Desalination Plants

- Sea Water Intake

- Industrial Sewage

- Hydropower Plants

- Fire Fighting lines in Industrial Complexes

- Petrochemical Complexes