GRP Piping System

AvisaParseh Manufacturing and Industries

Brief Pipe Specification and Technical Data

- Product Range

| Diameter Range | 300-3000 mm |

| Pressure Rating | up to 32 bar (depending on pipe diameter) |

| Stiffness Class | up to 10000 Pa |

| Standard Length | 12 meter |

- Installation

AvisaParseh GRP pipe can be installed in a number of different situations including above ground, sub- aqueous, trenchless and sloped applications. These applications often require more initial planning and more design considerations than the standard buried pipe installation. Specific instructions have been developed and could be provided when needed.

- Flow Velocity

Maximum recommended flow velocity is 3.0m/sec. Velocities of up to 9m/sec. can be used if the water is clean and contains no abrasive material.

- UV Resistance

There is no evidence to suggest that ultraviolet degradation is a factor that affects the long-term service life of GRP pipe. The outermost surface will be affected with discoloring of the surface which has no effect on the mechanical properties of the pipe.

- Possion’S Ration

Poisson’s ratio is influenced by the pipe construction. For AvisaParseh pipe, the ratio for hoop (circumferential) loads and axial response ranges from 0.22 to 0.29. For axial loading and circumferential response Poisson’s ratio will be slightly less.

- Operating Temperature

Maximum allowable temperature for GRP pipes produced using unsaturated polyester resin is 45 C. However, Avisaparseh Resin Manufacturing division has designed specially formulated resins which under certain operating condition could withstand tempeatures up to 160 C.

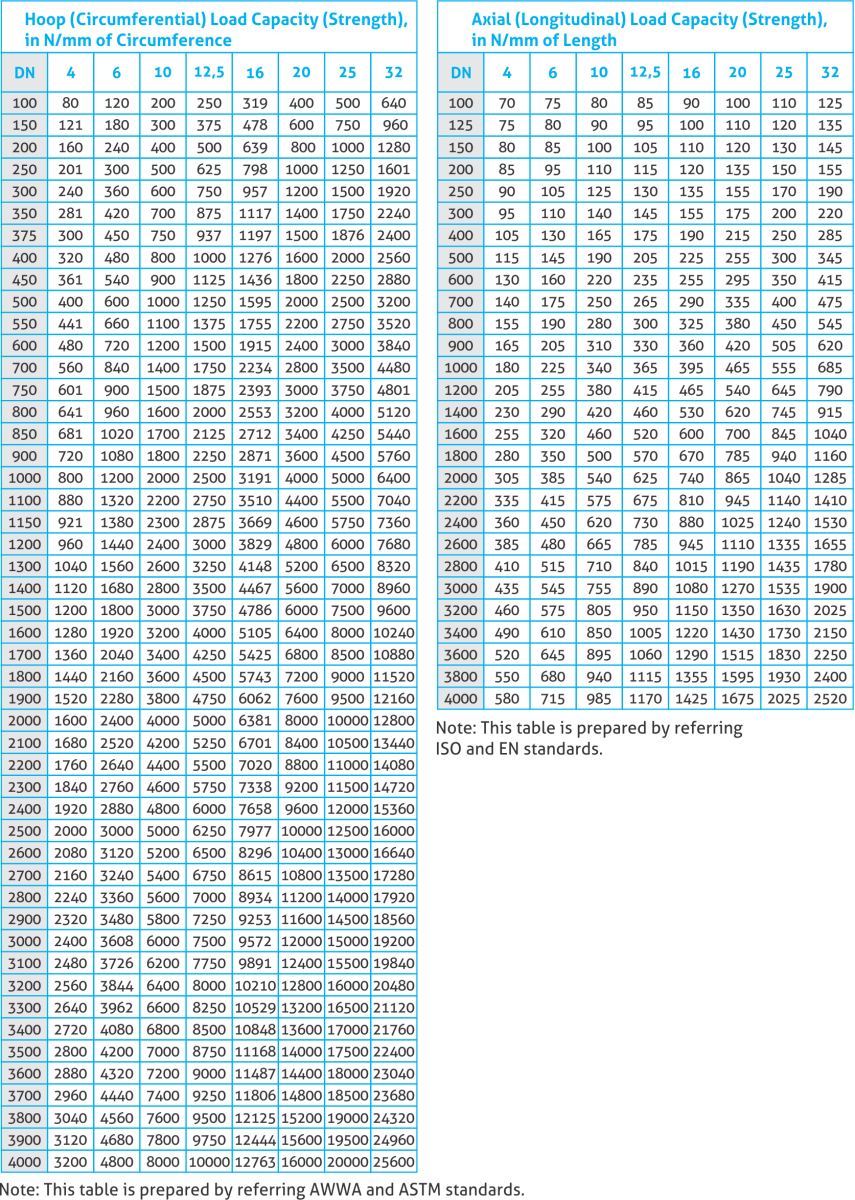

- Load Capacity Values

- Thermal Coefficient of Expansion

The thermal coefficient of axial expansion and contraction for GRP pipe is 21 to 28x 10-6 cm/cm/C which in longitudenal direction is almost 2 times larger than that of steel pipe.

- Flow coefficient

Based on long term tests carried out In Faratech Technology Center, for Avisaparseh GRP pipes, the Colebrook-White coefficient may be taken as 0.029mm. This corresponds to a Hazen Williams flow coefficient of approximately C=150 and Mannining flow coefficient of n=0.009

- Abrasion Resistance

Abrasion resistance can be related to the effects that sand or other similar material may have on the interior surface of the pipe. GRP pipe has been evaluated by using the Darmstadt Rocker method. The average abrasion loss of GRP pipe is 0.34mm at 100,000 cycles. Results will depend on the type of abrasive material used in the test.

- Hydrotest

- Maximum Test Pressure based on ASTM D3517 2*PN

- Maximum Field Test Pressure 1.5 PW

Get more information on GRP Pipe products, Technical and Specifications, Transportation, Installation and More

Learn More About International Standards, Test Methods, Best Practices and Specifications Applicable to GRP Piping Systems

Need Advice on selection of best solution for your particular application and project? Just send us an email or talk to us live through WhatsApp